GGS-QBG Mobile

High-Pressure Safety Valve Calibration Bench

Structural Features

- Equipped with GGS-QBG gas booster, it can directly increase medium-pressure gas to high pressure, ensuring on-site Safety Valve Calibration with unmatched precision.

- This equipment does not require electricity, and the boosting and calibration systems are integrated. The calibration table and boosting table combine into a high-pressure mobile unit—ideal for Safety Valve Calibration—or can be used separately for effortless transport and setup.

- Equipped with a hydraulic lifting work vehicle, it can lift the table to an ideal height, which

is convenient for transportation and on-site operations. - Equipped with a special aluminium alloy tool box, it is convenient to bring tools and

calibration table accessories to the site for calibration. - The clamping force of 1-9 tons can be adjusted stepless according to different calibers

and pressures. - Dual precision pressure gauge display, more accurate calibration.

- The safety protection baffle with calibration high-pressure safety valve greatly improves

the safety performance. - The pneumatic clamping structure is clean, fast, has a low failure rate, and is easy to

operate. - The operating valve uses high-quality military valves.

- The equipment is equipped with a safety valve with an automatic opening protection

device for clamping overpressure. - The equipment frame and table are made of stainless steel.

Technical Parameters

- Calibration range: DN20~200mm

- Maximum calibration pressure: 32MPa (320 bars)

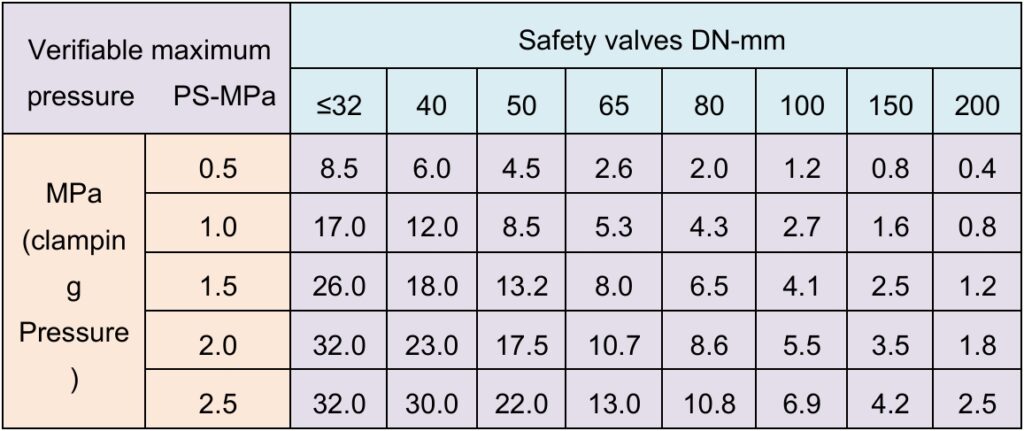

- This equipment adopts an adjustable clamping force structure, with a clamping force of 1 to 9 tons and stepless adjustment. When adjusted to the corresponding clamping pressure, the maximum pressure that can be calibrated for each gear diameter is shown in the table below:

Note: This check seat is an adjustable clamping force structure, which must be adjusted according to the diameter and cracking pressure of the safety valve to be calibrated. Otherwise, the clamping pressure is too high, which will damage the safety valve to be calibrated; the clamping pressure is too low, and the sealing requirements cannot be met. For details, see the above table.

Note: This check seat is an adjustable clamping force structure, which must be adjusted according to the diameter and cracking pressure of the safety valve to be calibrated. Otherwise, the clamping pressure is too high, which will damage the safety valve to be calibrated; the clamping pressure is too low, and the sealing requirements cannot be met. For details, see the above table. - Calibration accuracy: ±0.4%

- The calibration medium is nitrogen or clean compressed air, and the medium source is prepared by the user. This equipment should not be used to test other valves.

Equipment Configuration

High-Pressure Safety Valve Calibration Bench

| Description | Size | Qty |

| Test bench | Dimensions: 890×540×270mm Weight: 100kg | 1 Set |

| Booster unit | Dimensions: 890×540×310 mm Weight: 64 kg | 1 Set |

| Precision | 0~1.6MPa、0~4.0MPa、0~16MPa、0~ | 2 pcs each |

| Clamping foot | New forged two-way clamping foot | 1 pairs |

| Center pad | DN20、25、32、40、50、65、80、100、150、200 | 1 pcs each |

| Inch thread seat | ZG1/2″、3/4″、1″、1 1/4″、1 1/2″、2″、2 1/2″ | 1 pcs each |

| Metric thread seat | M27×1.5、M30×1.5、M33×1.5 | 1 pcs each |

| Transition pad | Blue | 1 pcs |

| O-ring | Related Sizes | Total 30 pcs |

| External air | M16×1.5 、 M20×1.5 L=3.5 m | 2 pcs |

| Close head | 1 pcs | |

| Safety guard | 1 pcs | |

| Hydraulic lift work | SP300 | 1 pcs |

| Toolbox | Aluminium Alloy | 1 pcs |

| Backup drive | Two-position three-way (large) | 1 pcs |

| Backup reset | Two-position three-way (emergency stop switch) | 1 pcs |

| Spare pinch valve | SF-5 | 1 pcs |

| Technical date | Instruction manual, certificate of conformity, pressure gauge calibration certificate | 1 pcs |