Our Company

Our History

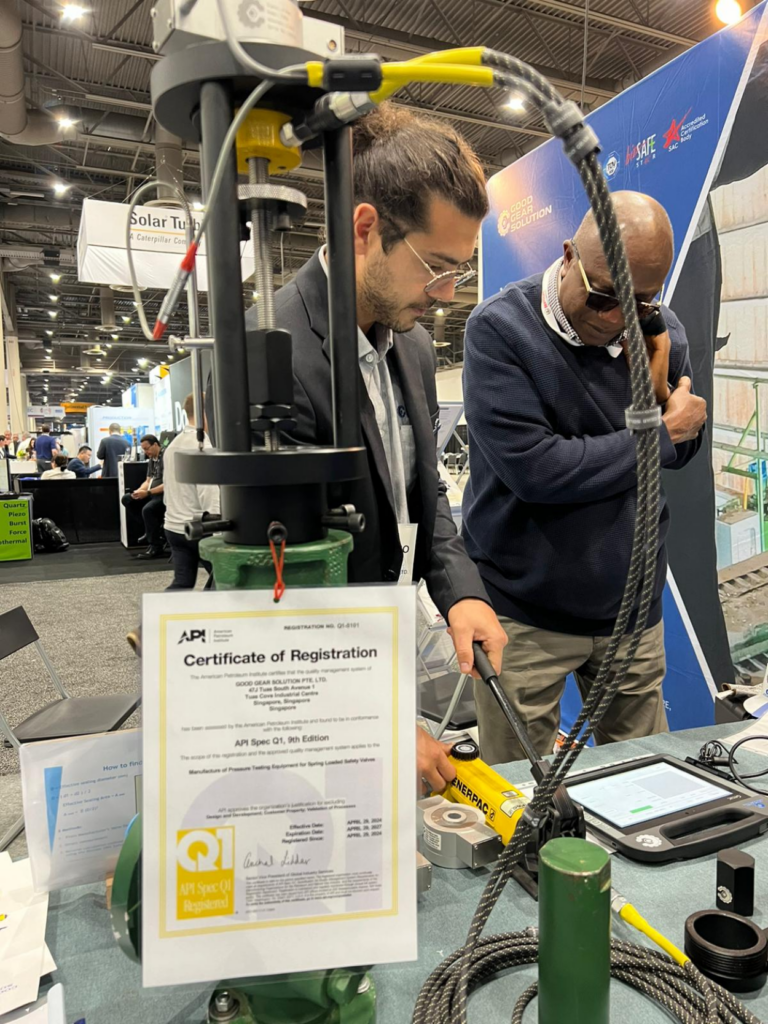

Good Gear Solution Pte Ltd is a company that was established in 2018, but its roots and experience in the PSV (Pressure Safety Valve) testing field can be traced back over 15 years. Over the years, Good Gear has focused on developing devices for both liquid and gas applications. It has gained extensive expertise in controlling and measuring pressure, temperature, and flow of various fluids.

In addition to its expertise in control and measurement, Good Gear is known for its proficiency in designing and developing “easy to test” solution packages that can be implemented on-site at factories. This capability allows customers to test their equipment without significant disruptions to their operations conveniently.

Good Gear‘s devices have been supplied to various industries, including aviation, oil, gas, and nominal industries. The company prides itself on providing technical innovations that meet the evolving needs of its customers. By continuously improving its products, Good Gear strives to deliver solutions.

Our Mission

Our mission is to designing and developing “easy to test” solution package at site of the factories. To provide solutions to ensure the safety of the factories with our valves.

The concept of sincere cooperation and innovation research and development, and the idea of being friends with users. Advancing the industry worldwide.

Our Vision

To always innovate and produce a solution that will meet the requirements of the customer.

Our Core Values

People: People and Passion are the core of our business and team. We care for the welfare of our people and have passion in all we do.

Process (Time): We believe that the journey or the process is the most important in everything we do, hence Professionalism is the core guiding principle in all that we do.

Product (Quality): Ensuring the Quality of the product we deliver is important in guiding our actions.

Public (Safety): We Care about the wellbeing of the community.

Philosophy (Cost): Integrity guides all our actions.

Our Commitment to Quality

The basic orientation of Good Gear is to be recognized for quality in the manufacturing of testing equipment for safety valves. This will be achieved through:

- Consideration of context of the organization and aligning the Integrated Management System with the strategic direction of Good gear

- Satisfying customer and applicable statutory and regulatory requirements

- Management of organization, along with employee-established quality objectives and defined responsibilities for their fulfillment

- Establishing, applying, maintaining and continual improvement of effectiveness of Integrated Management System based on ISO 9001:2015, ISO 14001:2015 and ISO 46001:2018

- Continual enhancement of customers’ satisfaction

- Tracking and applying new technologies and educating employees

- Careful selection of vendors and suppliers

- Commitment to increase quality of our product in order to exceed customers’ expectations

- Making continuous improvement a part of everyday

- Ensuring that our Policies and Procedure Manuals reflect what we actually do

- Understanding how our jobs fit into the overall flow of work at Good Gear

- Continuously upgrading the Integrated Management System in all stages manufacturing

The framework for setting quality objectives is defined in the IMS Manual. The Management Representative is responsible for communicating the Quality Policy to all persons working for or on behalf of the organization and making it available to the public.

Our Commitment to the Environment

Considering the purpose and context of the organization, and the condition of the environment in which the company operates, the management of Good Gear is committed to the continual improvement of the Integrated Management System (IMS), according to compliance obligations, by following the principles and requirements of ISO 14001: 2015, ISO 9001:2015 and ISO 46001:2018.

The framework for setting environmental objectives is defined in the IMS Manual. All employees of Good Gear are acting to protect the environment by preventing and eliminating environmental pollution through:

- Continual education in order to prevent environmental pollution, preserve natural resources, and improve the IMS

- Continual raising of environmental awareness

- Continual legal compliance

- Exploration of new materials with smaller environmental footprints and improvement of hazardous waste management

- Decrease of nonrenewable energy consumption and replacement with renewable energy sources

- Following environmental procedures in order to decrease environmental pollution , and prevent degradation and damage to the environment

- Decrease of adverse impact on water, soil, air, and biodiversity.

The Management Representative is responsible for communicating the Environmental Policy to all persons working for or on behalf of the organization and making it available to the public.

Our Commitment to Health and Safety

Safety of our employees is of utmost importance along with quality, operation and cost-control. The maintenance of safe operating procedures at all times is of both monetary and human value, with the human value being far greater to the employer, the employee and the community. The following principles support this policy:

- All injuries and accidents are preventable through the establishment of and compliance with safe work procedures;

- The prevention of bodily injury and safeguarding of health are the first considerations in all workplace actions and are the responsibility of every employee at every level within the organization;

- Written safety plans describing safe work practices and procedures to be utilized in all workplace actions are essential elements of the overall workplace safety program. All employees at every level are responsible for knowing and following these practices described in the written safety plans;

- Each of us as employees is responsible for adhering to those safe work practices; and

- Off the job, all employees should be similarly safe and demonstrate awareness of potential hazards.

- We are committed to seek to exceed customer expectations and their requirements and continually improve the performance of the business and QHSE management system. We will demonstrate QHSE commitment and accountability from all level of the organization.

- Zero Fatality

- Reduced risks at work stations

- Preventing environmental impacts

- Reduced waste and improved recycling

- Identify and eliminate all hazards in the working environment

- We are committed to reduce OH&S risks and commitment to consultation and participation of workers taking every feedback from the workers seriously.

The impact of our products

Customer distribution map

Munich

Brussels

Hong Kong

Barcelona

Kazakhstan

Guatemala

Sri Lanka

South Korea

Tunisia

Uruguay

San Francisco

Sydney

Tokyo

Bolivia

Chile

PHILIPINES

Indonesia

Brunei

Myanmar

Singapore

Nigeria

OMAN

ITALY

Yemen

Brunei

Ireland

Malaysia

Qatar

Cambodia

PERU