Online Safety Valve Testing Equipment

Pioneer Test+ (Pressure Safety Valve Testing Equipment). Specializing in liquid and gas applications, we excel in the precise control and measurement of pressure, temperature, and fluid flow.

Product branding

Welcome to Good Gear Solution – Pioneers in Safety Valve Testing and Verification

Established in 2018, Good Gear Solution Pte Ltd brings over 15 years of specialized expertise to the Pressure Safety Valve (PSV) testing field. Specializing in liquid and gas applications, we excel in the precise control and measurement of pressure, temperature, and fluid flow.

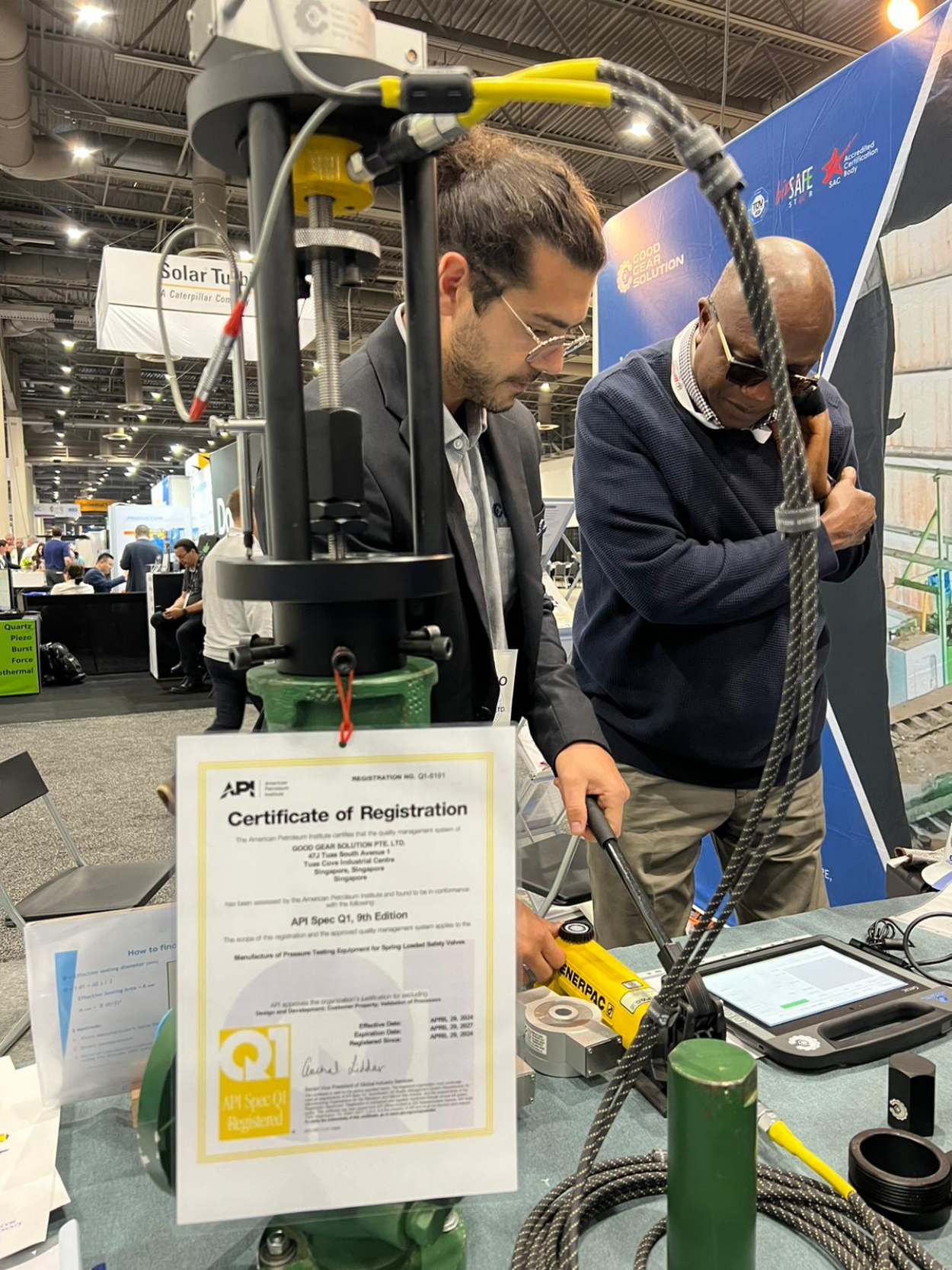

Our clientele includes multinational corporations, government-owned chemical companies, industrial gases suppliers, and petroleum enterprises. Introducing our state-of-the-art solution: Pioneer TEST Pressure Safety Valve Testing System.

Choose Good Gear Solution for unparalleled safety valve testing and verification. Our advanced systems guarantee optimal safety, compliance with regulatory standards, and substantial savings in time and costs. Trust us for the protection your equipment and personnel deserve.

User-friendly, compact, light, safe, and portable for testing at any location.

WHAT WE DO

Pioneer TEST Safety Valve Testing System: Revolutionizing Safety Valve Testing

In-line detection

Good Gear Solution official Twitter, Get more updates on safety valve in-line inspection products.

Affordable Package

Online safety valve testing for on-site training for customers. Focus on exquisite service.

Accreditation

Authoritative quality assurance, Good Gear Solution has received several certifications.

Our Excellence and Dedication:

Good Gear Solution is renowned for designing “easy-to-test” solutions, enabling on-site implementation at factories, ensuring equipment testing without significant disruptions. Our devices find application across various industries such as aviation, oil, gas, and nominal industries. Committed to continuous innovation, we ensure our products meet the highest quality standards.

Non-stop valve testing

In industrial settings, our Pioneer TEST Pressure Safety Valve online testing system is a beacon of efficiency for reliable safety valve verification and repair services. With two decades of practical experience, we’ve developed a system that evaluates valve functionality during operation, eliminating the need for dismantling. This ensures precise assessments under actual operating conditions, enhancing emergency problem-solving and maintenance capabilities without disrupting equipment operation.

Online safety valve testing

Key Features & Benefits of Pioneer TEST Pressure Safety Valve Test System:

Pioneering Safety

Can be operated online or offline without valve dismantling.

Safety valve testing training

Ensures accurate assessment under actual operating conditions.

Online testing without downtime

Versatile and efficient for emergency problem-solving.

Online solutions and device support

Time and cost-effective while maintaining optimal safety.

Technical Support

Effectively re-adjusts safety valves without changing set or popup pressure.

Customer training

Facilitates “annual inspections” and adjustments online.

Online safety valve testing

Unique Features & Benefits of Pioneer TEST Pressure Safety Valve Testing System

Portable Marvel for Valve Verification:

Our Pioneer Plus safety valve online and offline verification instrument is meticulously designed for major industries. Crafted from aviation-grade material, it ensures safety during online and offline testing.

1.Constructed from lightweight Aviation-grade Aluminum alloy, the mechanical fixture incorporates a frame-level avoidance function, significantly enhancing the efficiency of safety valve debugging.

2.Packed in an industrial and military-grade travel case, weighing approximately 28 kg. When backpacked, the unit weighs about 16 kg.

3.The travel case is resistant to shock, explosion, water, chemical corrosion, and extreme high temperatures.

In-situ, On-line & Offline Valve Testing:

1.The multi-functional threaded and non-threaded connection accessories, also crafted from Aviation-grade Aluminum alloy, successfully address the diversity of valve stems, thereby improving connection applicability.

2.Enables testing without line pressure both online and offline.

3.Filters out valves not requiring repair during major overhauls.

4.Ideal for small and large-diameter, high-position valves, resulting in time and cost savings.

5.Tests valves connected in series, minimizing downtime and risks.

Fast & Reliable:

1.A reliable tool for re-adjusting valves affected by transportation or installation.

2.The system can be set up and operated to test the valve within 10 minutes.

3.A safe and reliable limit closing mechanism with limited valve flap rise to less than 1mm without disturbing the production process.

4.Data cables are shielded to safeguard against electrical noise interference.

5.Valve test reports are meticulously structured and straightforward for easy interpretation.

Safety Features:

1.Ergonomic design ensures simplicity in assembly and use, safety, and reliability.

2.Assures the safe setting of opening pressure for various operating media.

3.Testing of Safety Valve ensures the system is protected from overpressure conditions, ensuring personnel and equipment safety.

4.No contact with process media during the test.

5.During testing, the pop-up or opening can be precisely set to prevent excessive discharge or protect on-site personnel.

6.Data & hydraulic cables are insulated with high-temperature heat-resistant thermal material.

7.Quick disconnect hydraulic coupling with a locking feature.

On-site safety testing of valves

This robust and light-weighted equipment provide precise testing of pressure safety valves on regular basis without dismantling the valves or shutting down the plant.

Online Safety Valve Testing

Introduction Of Safety Valve Online Testing Equipment

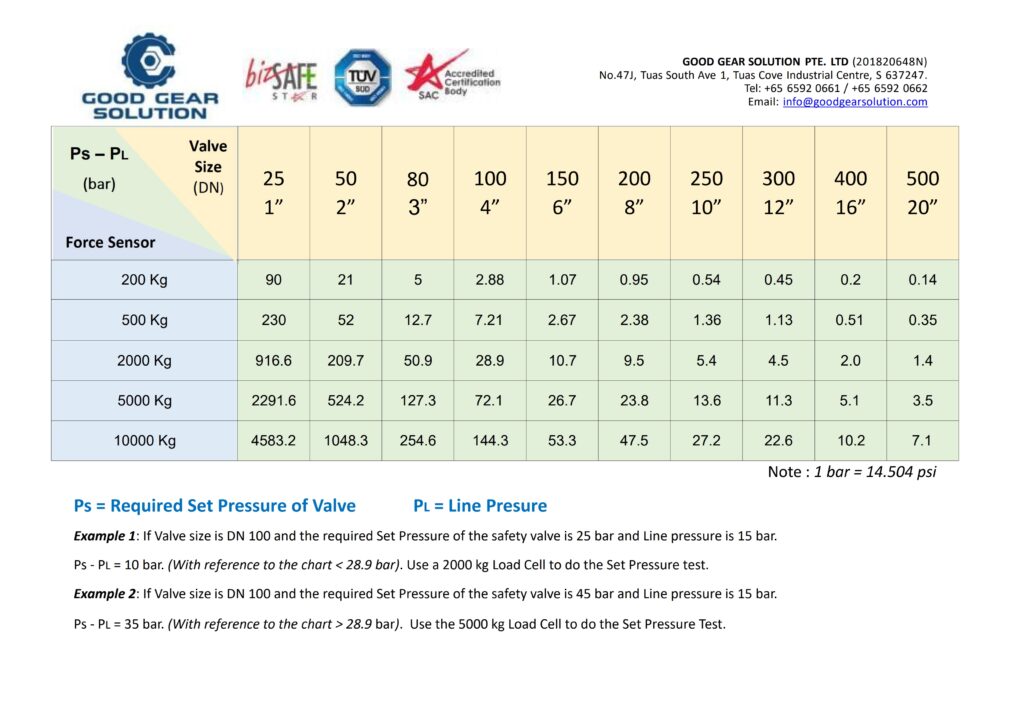

1. Outer Force: Manual Hydraulic Pump

2. Up-force scope: 0-50KN (optional could be 200KN)

3. Force sensor range: 2-5KN, 20-50KN

4. Working method: auto-partition accuracy: 0.4% F.S

5. Power: inside and outside Li-battery (Large capacity battery is an option)

6. Working Temperature: Operating temperature: -21 ° C – 60 ° C; storage temperature: -40 ° C – 71 ° C.

7. Industrial three proofing’s computer

8. 4″ LED High brightness touch screen supported outside reading

9. Operating system: windows 10

10. Processor: Intel Atom